Industry knowledge

Are there any limitations or considerations when using hollow wall panels in construction?

Structural Support: Hollow wall panels rely on proper structural support to ensure their stability. The supporting framework must be designed and installed correctly to bear the load of the panels.

Installation Expertise: Proper installation of hollow wall panels requires skilled labor and specialized knowledge. It is important to work with experienced professionals who are familiar with the installation process to ensure the panels are properly aligned, secured, and sealed.

Moisture Protection: Hollow wall panels may be susceptible to moisture infiltration if not adequately protected. Proper moisture barriers and sealants should be employed to prevent water damage and maintain the integrity of the panels.

Limited Load-bearing Capacity: Compared to traditional solid wall construction, hollow wall panels have a limited load-bearing capacity. This means that additional structural support may be necessary for certain applications or if heavy objects need to be hung on the panels.

Sound Insulation: While some hollow wall panels offer sound insulation properties, they may not provide the same level of acoustic performance as solid walls. If soundproofing is a critical requirement, additional measures may be needed, such as using acoustic insulation materials or double-layering the panels.

Limited Wiring and Plumbing Accessibility: Once hollow wall panels are installed, accessing wiring, plumbing, or other utilities within the walls can be more challenging compared to traditional construction methods. Adequate planning and coordination with electricians and plumbers are necessary to ensure future access, maintenance, and modifications.

Long-Term Durability: The long-term durability of hollow wall panels depends on the quality of materials used, installation techniques, and maintenance. It is crucial to choose reputable manufacturers and employ proper maintenance practices to ensure the panels retain their performance and appearance over time.

Are hollow wall panels structurally strong and durable?

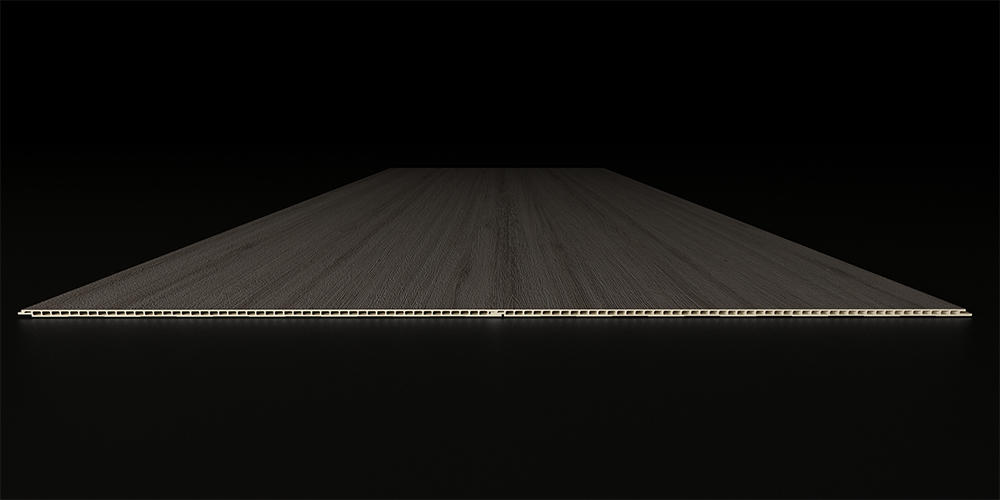

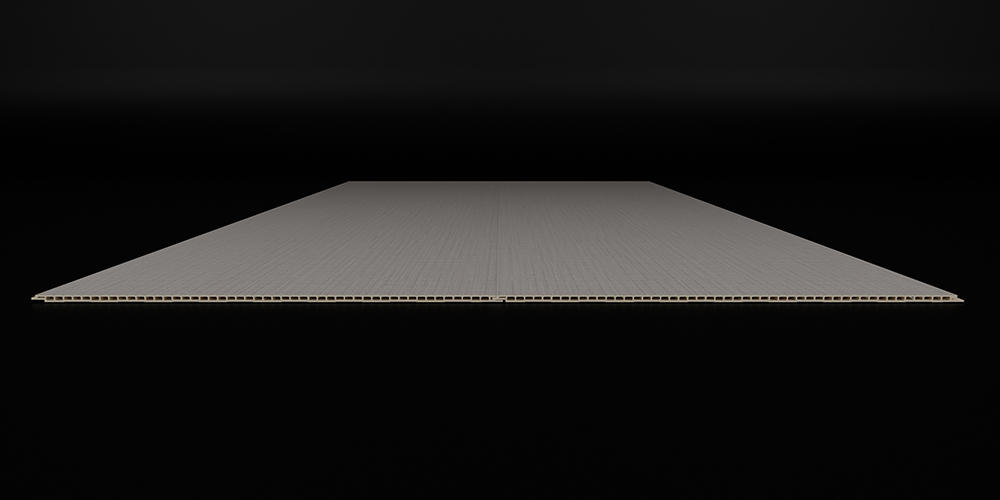

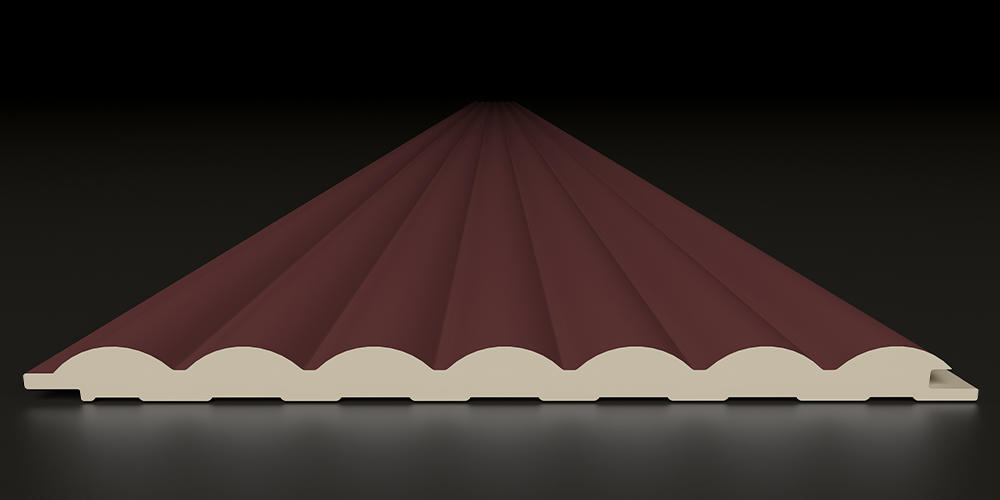

Design and Materials: The design and choice of materials greatly influence the strength and durability of hollow wall panels. High-quality materials such as reinforced concrete, steel, or composite materials are commonly used to enhance the structural integrity of the panels.

Manufacturing Standards: The panels should be manufactured in accordance with industry standards and quality control processes. Adhering to these standards ensures that the panels meet specific strength and durability requirements.

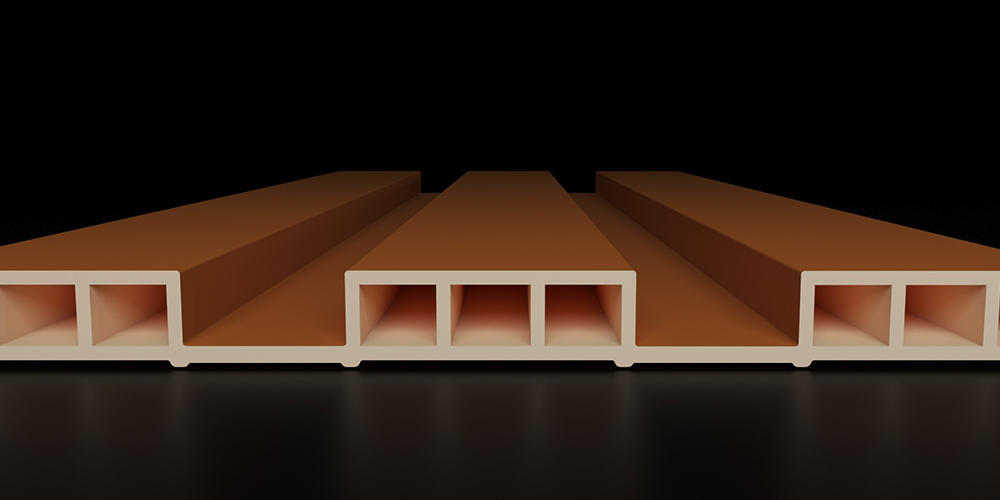

Load-Bearing Capacity: Hollow wall panels can be engineered to have adequate load-bearing capacity based on the intended application. The panels' thickness, reinforcement, and design factors such as ribbing or truss systems can be incorporated to enhance their ability to bear weight and resist structural stresses.

Installation Techniques: Proper installation is crucial for ensuring the structural strength and durability of hollow wall panels. Skilled professionals should follow the manufacturer's guidelines and best practices for installation, including adequate anchoring and sealing methods.

Maintenance: Regular maintenance is essential for preserving the strength and durability of hollow wall panels. This may include inspections, repairs, and preventive measures to address any signs of wear, damage, or moisture infiltration.

Environmental Considerations: Environmental factors, such as exposure to extreme temperatures, moisture, or corrosive elements, can impact the longevity of hollow wall panels. Choosing materials that are resistant to these conditions or employing protective coatings can enhance their durability.

Longevity: The lifespan of hollow wall panels can vary depending on various factors, including material quality, installation quality, and maintenance practices. When properly designed, manufactured, installed, and maintained, hollow wall panels can have a long lifespan comparable to traditional solid walls.

.jpg?imageView2/2/format/jp2)