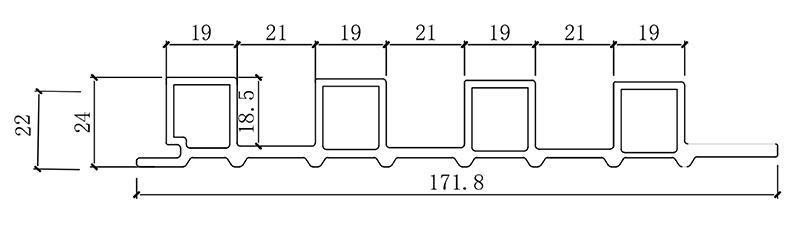

| Width | Thickness | Density |

| 171.8mm | 22/24mm | 870g/m / 1000g/m / 1070g/m / 1200g/m |

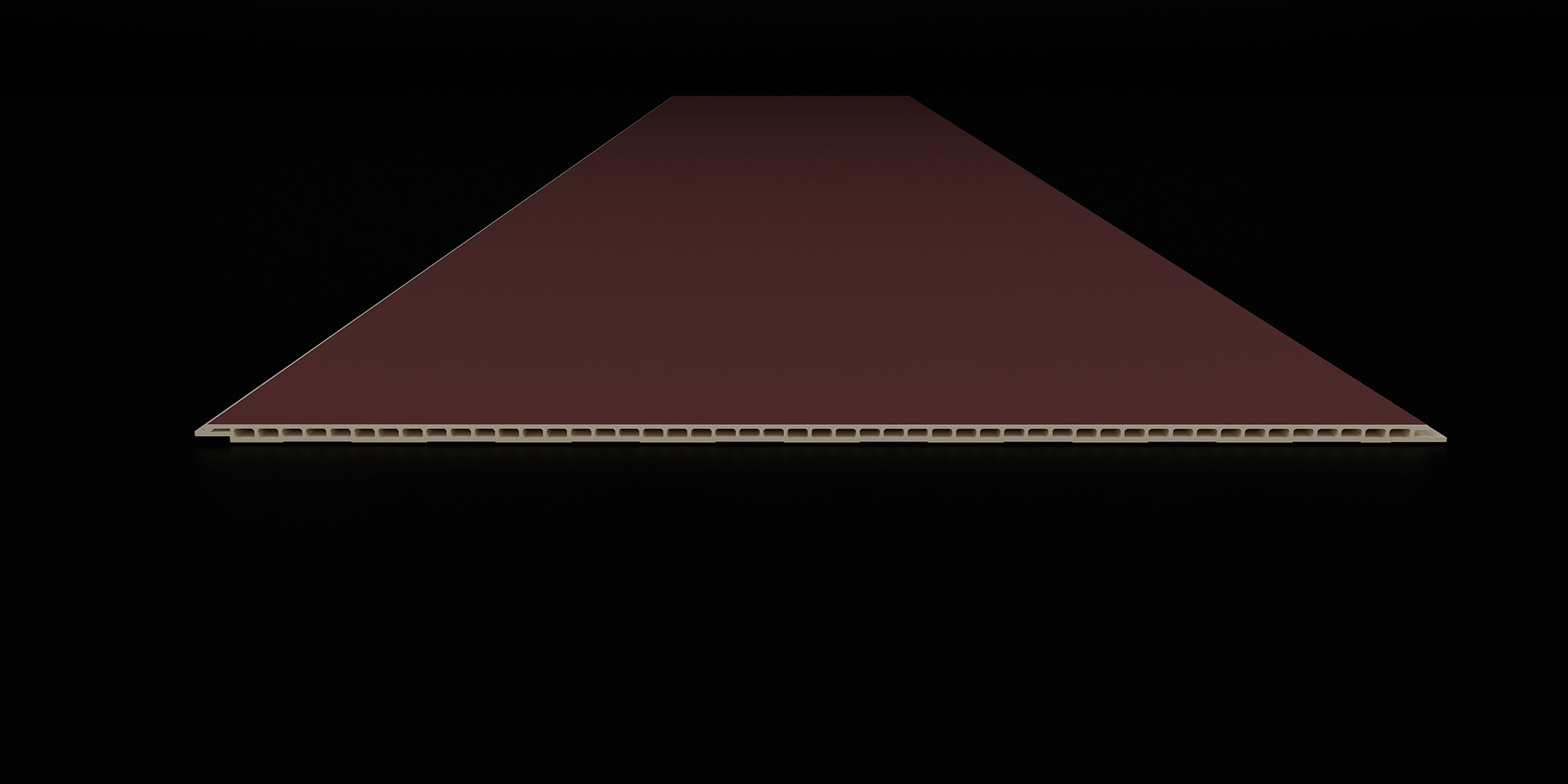

The 170 mm WPC wall fluted panels are accessory with a width of 170 mm, a thickness of 24 mm and a density of 870 g/m. Its most important feature is thickness (height) which is greater than other similar products, resulting in deeper grooves, so the effect of splicing is more stereoscopic.

The 170 WPC wall fluted panels are WPC wall slated panels with both value and strength. Not only Fire Resistant wall board, but also Waterproof wall board and moisture-proof wall panels. It has eight features that reflect the most beautiful life: fire retardant, waterproof and moisture resistant, upgraded and thickened, easy to install, green, insect and moth resistant, tough material and a wide choice of film colours.

Made from natural bamboo fibers, the 170 WPC wall fluted panels are formaldehyde-free, odor-free, durable and non-deformed, water- and wear-resistant. Concerning traditional decorating problems such as mold and mildew, slated panels can solve the problem at once, making it convenient and hassle-free.

The 170 WPC wall fluted panels are mortise and tenon slot in design, seamlessly spliced, more stable and natural, highlighting the overall fluidity. Whether for public buildings such as hotels and exhibition halls, or for the decoration of residential homes, its walls, ceilings, backdrops and garden landscaping can be used.

| Width | Thickness | Density |

| 171.8mm | 22/24mm | 870g/m / 1000g/m / 1070g/m / 1200g/m |

Introduction to Wall Panels:

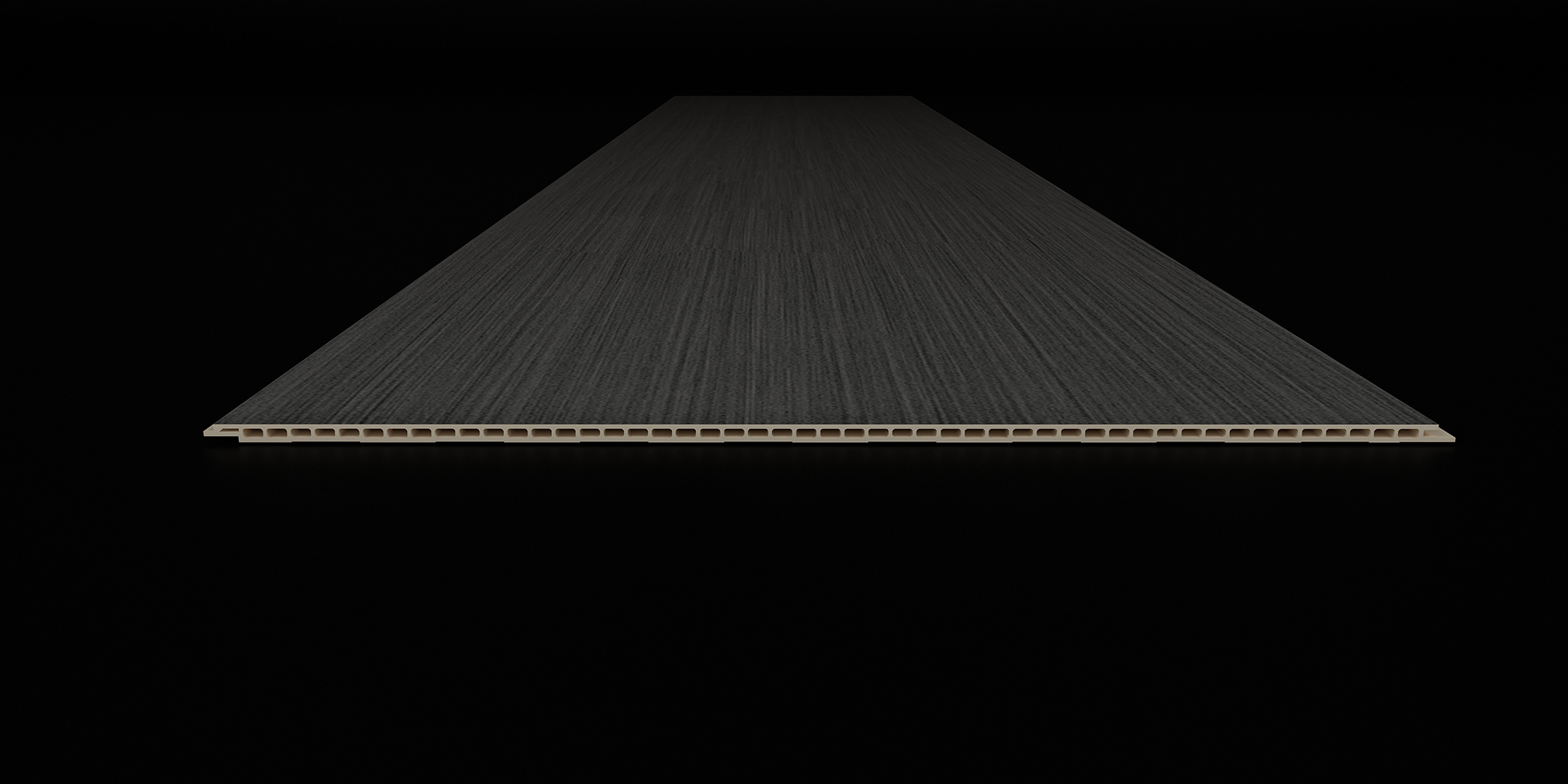

WPC wall panel is a new type of interior decoration material that integrates the traditional look of wood with the durability of composite materials. It has various specifications and a good decorative effect. It is often used in interior wall decoration.

Features:

It has the characteristics of lightweight, heat insulation, heat preservation, moisture-proof, waterproof, flame retardant, easy install, not easy to deform, moisture-proof, insect-proof and ant-proof. It solves the problem that many interior decoration materials are easy to rot, expand and deform after absorbing water in humid and watery environments.

With its dustproof, Eco-friendly, antibacterial,anti-ultraviolet,formaldehyde-free, corrosion resistance, easy cleaning, quick installation, various colors, waterproof and fireproof, mildew proof and so on.

Application:

WPC wall panel is suitable for all interior environment decoration,both for private use and commercial us,such as It can be used in many application scenarios, such as hotels, homes, bathrooms, schools, offices, hospitals, etc. Ideal for decorating or refurbishing building walls.

Commercial use

Commercial use

Commercial use

Commercial use

Commercial use

Commercial use

School

School

School

School

School

Hospital

Insoul is professional in production, design, research, and sales. We have a strong product research and development and design team which is very professional in color and structure. We can provide comprehensive wall assembly system solutions. And we have professional installation instructions and a full set of wall panel accessories, which can solve 99% of wall panel installation problems. If you want to know the product quality, samples can be sent to you for reference!

With an experienced and professional export team, we can help you solve many import problems with Chinese supplier, like consolidation, customs, transport etc.

● Deisgn

● Installation istruction

● Combination

● Sample

Artyzen Habitat Hotel Beijing

Yuhe International Hotel Beijing

The Beaufort Hotel Guangdong

GreenTree Hotel Group

Hangzhou Jiangnan Banquet Hotel

Geshan Prince Hotel Zhejiang

Shaoxing Xianheng Hotel

Sanmenwan Landison Square Hotel

Mountains Beyond The Mountains Building Changzhou

Changping University of Chemical Technology Beijing

Shanghai Sixth People's Hospital

Dongyang Second People's Hospital

Beijing Haidian District Government Office Building

Beijing Municipal Environmental Protection Bureau Office Building

Sichuan office in Beijing

Henan Building, Chaoyang District, Beijing

INSOUL works together with WPC wall panel inventor, with 10years of experience in WPC wall panel manufacturing and research, now we have more than 300 distributors in China mainland, and start exporting since 2020. We always remember to offer qualified interior wall panel products to customers and keep stable and sustainable suppliers for business partners.

As an enterprise that attaches great importance to brand building, INSOUL always insist on quality first, service best, pioneering and innovative, constantly updating structure and color, and leading the latest trend in the WPC wall panel industry.

NON-DECORATED HOUSE

WOOD STRUCTURE

STEEL STRUCTURE

PLASTERBOARD

CHIPBOARD

INSOUL WPC wall panel is Lightweight but strong, it is designed to install quickly and easily by Do-It-Yourselfers and professionals alike.

Whether you‘re considering DIY your own room or hiring a professional,our Installation instruction has everything you need to know when installing INSOUL products. We even can offer tools for you.

.jpg)

.jpg)

-3.jpg)

-1.jpg)

.jpg)

.jpg)