What is the difference between uv board and wpc wall panel

- Buy Ticket $29

- facebook event

- bandsintown event

1、Material difference

The main raw materials of UV board are calcium powder and PVC, the percent of calcium powder is very high ,the surface of UV board looks a bit like stone, but it is actually a synthetic product.

2、Surface treatment difference

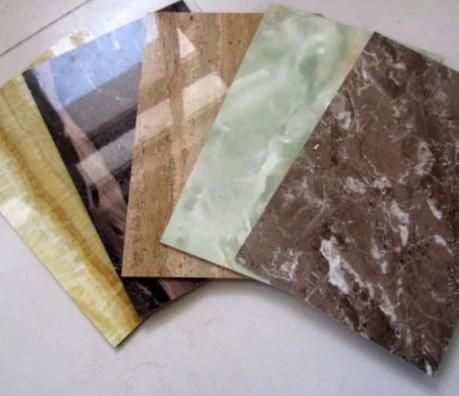

About the treatment of these two products, actually they both need secondary processing .See the surface film, the UV board uses a bronzing film, which is simple in process and cheap in cost. The surface of the UV board needs to be heat-transfer printing first, and then a layer of UV paint is attached to the surface of the board through the machine to make it look more shiny and smooth.

Wpc wall panel is a PVC film with various textures laminated to the surface od the baseboard, the quality is good and the process is complicated

3、Size difference

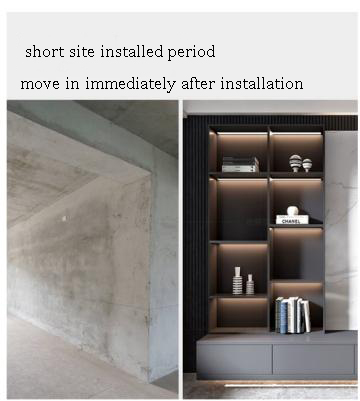

Wpc wall panel can be installed horizontally, vertically or obliquely according to personal preferences. The splicing adopts socket and snap-on design,and different styles of products can be installed and used with each other,providing designers with greater imagination space for personalized design.In addition,the processing method is the same as that of solid wood,which can be sawed, nailed, and planed,and can be used immediately without painting,Generally, woodworkers can install it with ease, which is light and fast. The whole house refurbishment has introduced a new concept of 15-day environmental protection and fast home improvement in the decoration industry.

5、Shipping Difference

The UV board needs to be packed into a pallet, too heavy and needs to be unloaded by a forklift, The cost of manual unloading is high, and the labor cost of go upstairs is high.

6、Environmental distinction

In the process of UV production, some heavy metal materials will be doped, so that the UV board will contain some harmful substances, which will easily lead to unqualified product quality. During the process of use, the board may emit harmful gases, so It will have some effect on our body. Moreover, the UV board needs to be painted with UV paint, but all decorative materials related to glue and paint will contain a certain amount of formaldehyde.

in conclusion:

The surface of the UV decorative board is protected by UV light curing paint.The base material is cement pressure board, solid wood multi-layer board, MDF, glass magnesium fireproof board four kinds.

Advantages: low cost, easy surface scrubbing, high brightness

Disadvantages: 1. Poor moisture resistance. In the humid environment of the kitchen, good moisture resistance is the most practical. UV cabinet door panels do not have good moisture resistance, so the service life will not be too long. 2. Poor high temperature resistance, easy to deform, and air bulge. 3. easy to paint off. If it is bumped, the paint is easy to fall off, and it is very troublesome to touch up the paint. All the paint surfaces must be cleaned before painting. 4, poor antibacterial properties, prone to insects. 5. Poor decoration. Because it is a flat plate, it cannot be arbitrarily shaped, and there are few patterns and three-dimensional sense. 6. The seams are dirty and cannot be taken care of.

Wpc wall panels are made of natural bamboo and wood fiber powder and heavy calcium powder as raw materials,by high temperature mixing,passed through a high-pressure extruder, and cooled by direct condensate water as the base plate;The surface is made of PVC polymer film at high temperature.

2.Moisture-proof. The whole body of the board is washable and easy to care for, and the blisters will not deform or fade for three years.

3.Sound insulation and thermal insulation. Because the board has air holes, it can effectively play the effect of sound insulation and heat preservation, saving the gas cost of floor heating in winter and the electricity cost of air conditioning in summer. 4. Effectively against wall cracking. If the wall is slightly cracked, the integrated wall will not be damaged. 5. Moth-proof and Strong antibacterial. It will not be like wallpaper and wall coverings. Over time, insects and bacteria will grow. 6,E1 grade environmental protection material, non-toxic, installed on the rough wall, 7-10 per home, and it can be installed and lived immediately. 7. The decoration is strong, the patterns are colorful, and the style of the whole line is casual. There are wood grain series, leather carving series, stone series, wallpaper wall covering series, relief series and other styles and color

8. Three-dimensional, tasteless, save time, labor and money.Don't shovel walls, don't scratch white, just be strong.

Disadvantages: The problem of thermal expansion and contraction, the flat seam is poor, and the gap is more obvious after a long time. The v-slit can solve the problem of thermal expansion and contraction, but there is a v-shaped groove, which some people don't like, but the three-dimensional effect is strong. Therefore, bamboo and wood fiberboards are best installed with special lines, which can not only solve the problem of thermal expansion and contraction, but also have various shapes, and can even be matched with lights to create a high-end luxury and warm feeling.