Soundproofing

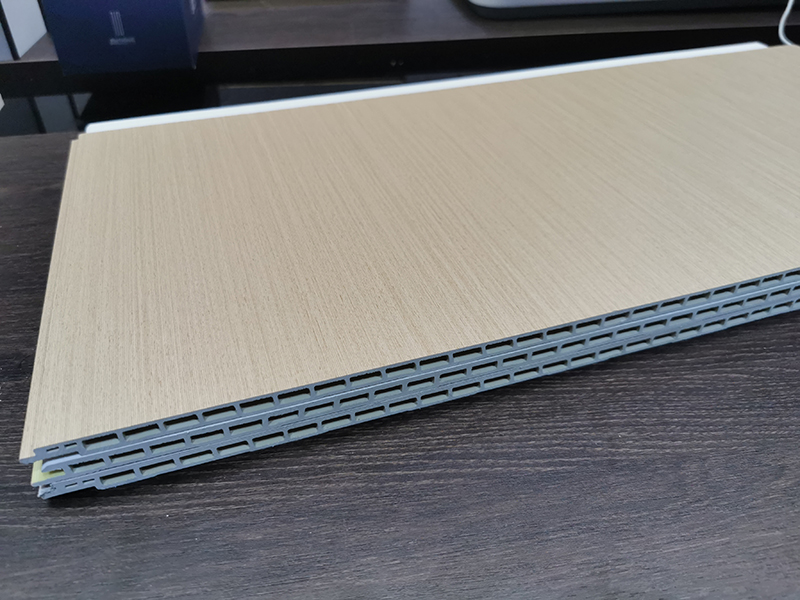

hollow wall panels involves incorporating materials and techniques that reduce the transmission of sound through the panels. While hollow wall panels themselves offer some degree of sound insulation due to their cavity structure, additional measures can be taken to enhance their acoustic performance. Here are some common methods used to soundproof hollow wall panels:

Use of Soundproof Insulation: Filling the hollow cavities of the wall panels with soundproof insulation materials can significantly improve their acoustic performance. Materials like mineral wool, fiberglass, or acoustic foam are often used to dampen sound vibrations and reduce noise transmission.

Double Wall Construction: Creating a double wall system by installing two sets of hollow wall panels with an air gap in between can effectively block sound transmission. The air gap acts as a sound barrier, preventing sound waves from passing through the wall.

Mass-Loaded Vinyl (MLV): Mass-loaded vinyl is a dense, flexible material that can be added to the surface of the hollow wall panels or installed within the wall cavity. It adds mass to the wall, which helps absorb and block sound vibrations.

Sealing Gaps and Joints: Properly sealing any gaps, joints, or seams in the hollow wall panels is essential for preventing sound leaks. Acoustic sealants or specialized soundproofing tapes can be used for this purpose.

Resilient Channel Mounting: Mounting the hollow wall panels on resilient channels or decoupling systems can reduce the transfer of vibrations from one side of the wall to the other. This method isolates the panels from the structure, further minimizing sound transmission.

Mass and Density: Increasing the mass and density of the wall panels themselves can enhance their soundproofing capabilities. Heavier panels are less likely to vibrate and transmit sound.

Acoustic Drywall: Using specially designed acoustic drywall panels in conjunction with the hollow wall panels can enhance soundproofing. These drywall panels have sound-absorbing properties and are ideal for interior spaces where noise reduction is crucial.

Green Glue: Green Glue is a viscoelastic compound that can be applied between layers of drywall or onto the surface of hollow wall panels. It converts sound energy into heat, reducing sound transmission.

Soundproofing Paint: Soundproofing paint or coatings can be applied to the surface of the wall panels to reduce sound reflection and absorption. While they provide limited soundproofing on their own, they can be part of a comprehensive soundproofing strategy.

Acoustic Paneling: Installing acoustic panels or panels with sound-absorbing properties on the interior surface of the hollow wall panels can further enhance soundproofing within a room.

It's essential to consider the specific soundproofing requirements of your project and consult with acoustic experts or professionals who can recommend the most appropriate combination of materials and techniques for your hollow wall panel system. The effectiveness of soundproofing measures may vary depending on factors such as the desired level of sound reduction, the construction environment, and the type of noise being addressed.